If you’re researching shot blast media, you’re likely looking for the right abrasive material to achieve the perfect surface finish. And rightly so. In industries where surface preparation is critical—like aerospace, automotive, metal fabrication, and marine—choosing the correct blast media can make or break the entire finishing process.

At Stacey Processing, we specialise in helping businesses find the most effective shot blast media for their unique operational needs. With decades of industry experience under our belts, we understand that not all abrasive materials are created equal. That’s why we offer a wide range of solutions tailored to specific surfaces, applications, and desired finishes.

Why Shot Blast Media Matters

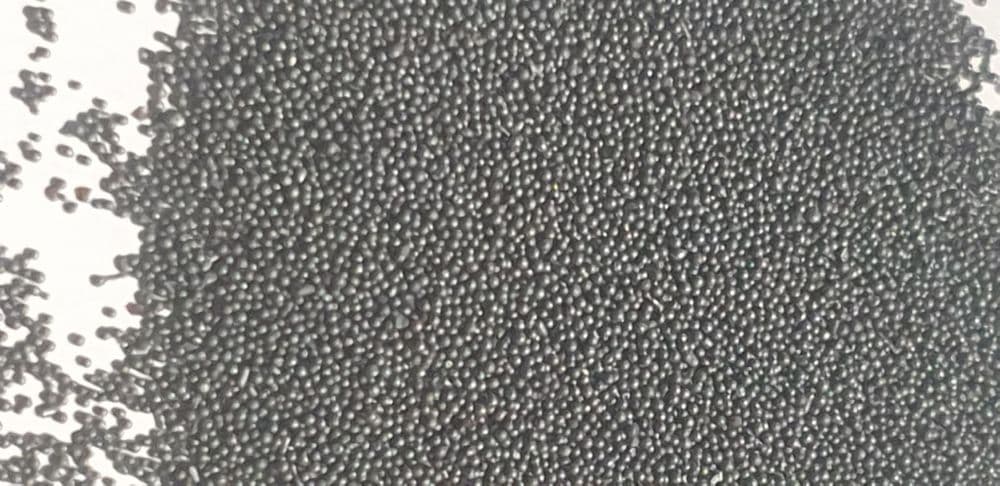

Shot blasting is a surface preparation method that propels abrasive particles at high velocity to clean, strip, or prepare materials for further processing. But here’s where many operations falter—they overlook the importance of selecting the right shot blast media.

Whether you’re preparing a steel structure for a powder coat, removing stubborn rust from industrial machinery, or cleaning delicate aluminium components, choosing the correct blast media is crucial. Not only does it impact the quality of the finish, but it also affects production efficiency, operational costs, and equipment longevity.

Common Types of Shot Blast Media

At Stacey Processing, we supply and advise on a wide variety of shot blast media, each with its own benefits, characteristics, and best-use scenarios. Let’s break down a few of the most popular types:

1. Steel Shot

This is a durable, reusable media ideal for heavy-duty cleaning and peening applications. Steel shot is spherical and provides a smooth finish, making it a go-to for large-scale operations in automotive and foundry industries.

2. Aluminium Oxide

A sharp, angular media perfect for aggressive surface cleaning. It’s commonly used in applications requiring precision, such as aerospace components and electronic parts. Aluminium oxide is also non-toxic and recyclable, aligning with modern sustainability goals.

3. Ceramic Beads

When a fine, uniform finish is required—especially on stainless steel or non-ferrous metals—ceramic beads are an excellent choice. They’re chemically inert and can be used in both dry and wet blasting environments.

4. Glass Beads

A non-aggressive, environmentally friendly media best suited for cosmetic finishing and light cleaning tasks. Glass beads leave behind a smooth, satin-like surface without altering the underlying dimensions of the part.

These are just a few examples. We also offer plastic media, walnut shells, garnet, and more, depending on your material sensitivity, environmental concerns, and industry regulations.

Tailoring Media to Your Application

If you’re researching shot blast media, you’re likely already aware that using the wrong material can lead to increased wear on equipment, uneven finishes, and even substrate damage. That’s where we step in.

At Stacey Processing, we work closely with you to analyse your application requirements—everything from base material and finish type to blasting method and operational constraints. Whether you need aluminium oxide for a fine finish or steel shot for robust surface cleaning, we’ll ensure your selected media aligns perfectly with your project goals.

We’ve helped hundreds of clients across the UK refine their blasting processes by simply upgrading their media selection—and the results speak for themselves: cleaner finishes, faster cycles, and lower equipment maintenance costs.

Our In-House Expertise

Being more than just a supplier, we see ourselves as technical partners. Our team comprises engineers and technicians who are deeply familiar with surface engineering and the science behind abrasive blasting. That’s why we’ve become a trusted name in shot blast media consultation and supply throughout the UK.

We also pride ourselves on maintaining stringent quality standards. All our media is rigorously tested to ensure consistent particle size, shape, and density—so you get uniform results every single time.

Supporting Sustainability & Efficiency

Another reason to choose Stacey Processing? We understand that environmental responsibility is now a cornerstone of modern industry. That’s why we offer eco-friendly blasting options, including recyclable media and low-dust alternatives, which help reduce your environmental footprint without sacrificing performance.

Our commitment to sustainability doesn’t end at our products. We provide comprehensive advice on media recovery systems, waste reduction strategies, and how to prolong the life of your equipment through optimal media use.

Why Choose Stacey Processing?

If you’re researching shot blast media, trust us—Stacey Processing is the team you want by your side. With our full suite of abrasive materials, customised consultation, and commitment to quality, we offer the perfect solution for all types of shot blast media applications. Whether you’re looking for heavy-duty cleaning, delicate finishing, or rust removal, we’ve got a solution tailored for you.

Let’s Get Your Surface Perfect

Ready to improve your blasting outcomes, reduce waste, and save on operational costs?

Contact Stacey Processing today for expert advice and high-performance shot blast media solutions. We’re here to help you get the job done right—first time, every time.